Eland Lodge Visit Charles Owen

About the Tour

Touring the hat shaped factory (yes, their factory building is shaped like a riding hat) in Wrexham, North Wales, it is easy to see why Charles Owen is world leading in riding hats and head safety. The purpose of the tour was to help stockists understand how the hats are made, from initial design to production, and everything in between to help advice you, the customer, how to choose the best hat for you. But at Charles Owen things aren’t that simple, not only do they make safe and stunning riding hats, but they also set the standards in head safety along with creating the most environmentally friendly ways to produce hats. Want to know more? Well come with us on our tour of the Charles Owen Factory.

Charles Owen History

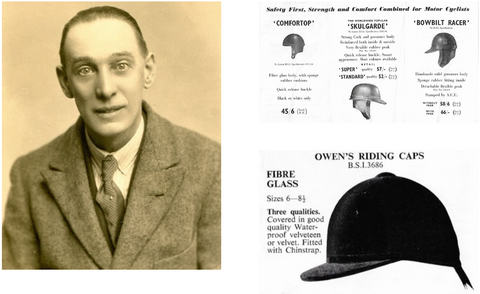

First stop on the tour was to see the history of Charles Owen and find out about the man himself pictured below. When Charles Owen himself founded the company in 1911, his mission was to make products ‘for a safer world’. The early days revolved around manufacturing military helmets which were worn by the British Army throughout the First World War. Soon after, the company expanded into motorsport protective headwear. Children in the family developed an interest in horse riding, and Walter (Charles Owen's Son-in-law) spotted an opportunity to design a riding helmet with safety being the priority. Riding helmets soon become the company’s flagship product and Charles Owen quickly established itself as the gold standard for safety. The company has remained within the same family for four generations, today under the direction of founder Charles Owen’s great-grandson.

During the tour we got to see some of the original military hats, motorcycle helmets and riding hats along with original furniture and paperwork from the first Charles Owen factory in London. It was certainly a step back in history!

How a Riding Hat is Made

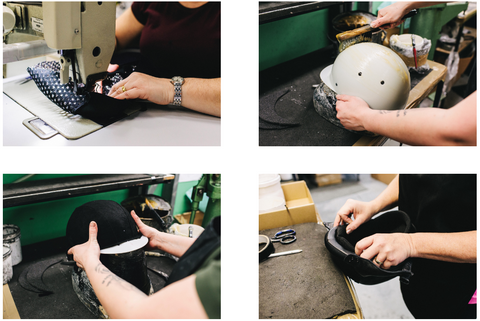

On our factory tour we got to see each stage of the hat making process. All done in one factory and by hand it was amazing to see these stunning hats put together. Here are the basics of how Charles Owen make their riding hats.

- Design and testing

Before a new riding helmet model hits the production line, it has gone through an extensive amount of design and testing. This involves in-house designers and engineers as well as external independent safety standard testing houses. - Expanded polystyrene (EPS)

The EPS layer of the helmet is critically important in protecting the brain from a fall. EPS is comprised of microscopic beads that act like bubble wrap for your head. These burst upon impact to absorb and dissipate the energy. Charles Owen now manufactures its own EPS using an ultra-refined recipe to produce the finest bubbles possible. - Fibreglass shell

The fibreglass material used for the helmet’s shell is first cut to size using templates. It is then set hard before being trimmed by hand with precision using a diamond-tipped router and sander. - Shell painting

The painting of shells is skillfully done by specialist spray-painters wearing protective equipment in a highly ventilated booth. - Cover stitching

Helmet covers can be made up of several different materials or fabrics. Each needs to be cut to size and then stitched together. - Cover applied

Glue is then applied to the surface if the shell is to be covered with mesh or material (microsuede, vegan leather-look or velvet). - Attaching the harness

Next, the harness is attached by rivets to the shell of the helmet. The harnesses themselves are sewn in-house, including our patented GRpx® harness that has five distinct layers that need to be stitched together. - Quality control

The final step of the process is cleaning and checking the helmet before it is passed through independent quality control. Highly skilled technicians handle this part of the production process to ensure that nothing is missed.

We had a go too! We had a race to see who was the fastest at putting on cover of a YR8 Hat, we weren't the fastest of the day but ours looked the best! We're Eland, so quality came first!

Getting to know Safety Standards and the Tests

Part of our tour included a presentation in Charles Owen's Home of Innovation, where they presented us with survey findings along with demonstrating hat testing and talking through which tests are needed for which standard. One thing that was quickly obvious is that Charles Owen wanted to improve the tests needed for hats to pass safety standards, making them even safer than they are today, with the sole aim of saving lives.

Why not take a look at your hat and see what standard it is. Compare it against this chart below and see what tests your hat has gone through to protect your head.Nearly all of Charles Owen helmets are triple standard: PAS015, VG1 and ASTM. This allows their helmets to deal with a higher number of situations, as the more standards awarded to a helmet the more they are tested in a greater variety of situations than a single or two standard helmet.

Did you know you can help improve safety standards? Charles Owen are constantly doing research into head safety, riding hats, head injuries and mental health. But to do this they need your help. If you have ever suffered a horse-related accident whilst wearing a Charles Owen product, then please complete an accident report form and this data will help keep riders safe.

Charles Owen Environmental Commitment

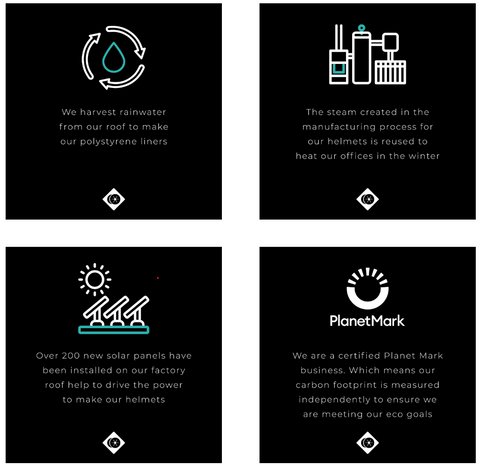

During our visit it was clear that for everything Charles Owen do, there is a thought for how it impacts the environmennt. For example when they make the polystryene insert for their hats they use water that has been collected from the rain off their roof. Any cut offs from fabrics are re-used as packaging for parcels, and solar panels on the roof power the factory. See below just a few of Charles Owen's Environmental Commitments.

Photos from our Tour

Book a hat fitting at Eland Lodge

In need of a new riding hat? Book a hat fitting appoitment with one of our friendly team, who can measure and fit you to a hat in store. All our team have recieved hat fitting training from Charles owen. Hat fittings are by appoitment only please email shop@elandlodge.com or call us on 01283 575856 to book. You can view all our hats on our website but we will not sell a hat without fitting it first. If a hat doesn't fit then it won't do it's job.